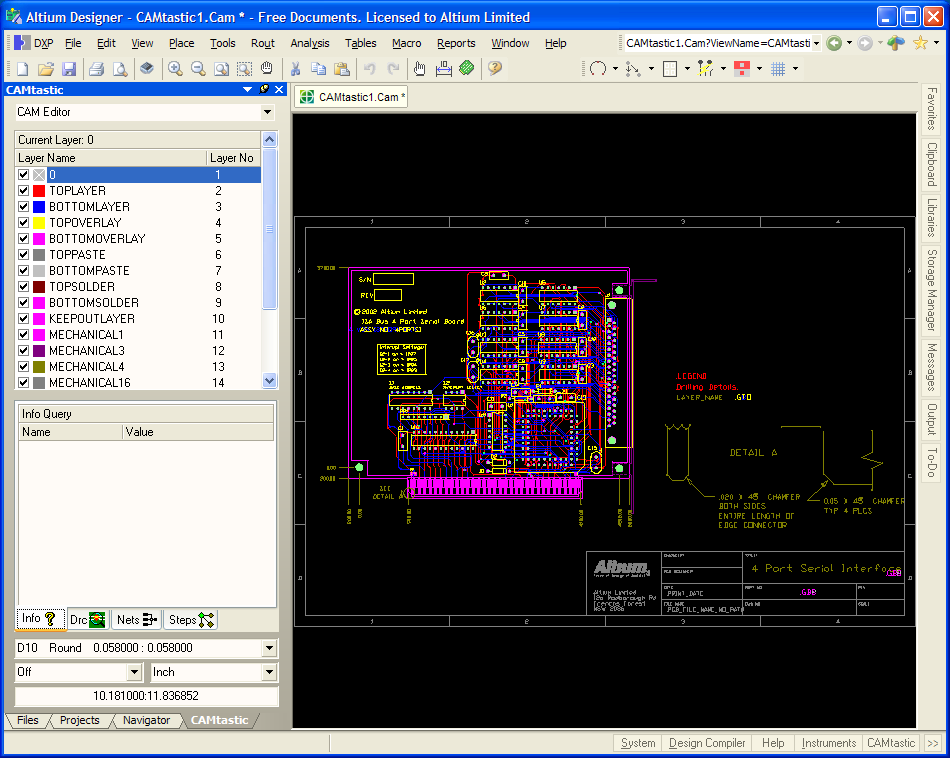

PCB design output is the files required by the manufacturers for designing the PCB. While working on a PCB layout, you edit a file that is exclusive to your CAD software. It’s not a universal file format, and the information it uses is unnecessary to the manufacturer. This is why you need to generate a different sort of file when you convert the schematic into a physical circuit board. Inside almost every electronic device is a PCB onto which the components are mechanically and electrically connected by soldering. PCB design uses a computer-aided design (CAD) system. To physically realize the design, the computerized design information must be transferred to a photolithographic computer-aided manufacturing (CAM) system. Since the CAD and CAM systems are generally produced by different companies, they have to agree on a CAD-to-CAM data exchange format to transfer the data.

ODB++

As we discussed earlier CAD-to-CAM data exchange format, ODB++ is such a format. When ODB++ is used, its data is stored in a hierarchy of files and file folders. While being transferred, designers will use common operating system commands that retain the hierarchy structure by fusing all of the data into one compressed file. ODB++ allows designers and manufacturers to transfer more than just the standard layer artwork and drill data. This is possible because of its hierarchical nature. ODB++’s unique file structure allows for large amounts of additional data to be included in a single file, including the material stack-up, bill of materials, and component placement, as well as dimension and fabrication data. ODB++ can be accessed through most PCB design programs (Expedition, PADS, Allegro), making it almost a universal format throughout PCB manufacturing (except Eagle).

IPC-2581

How To Open Dwg File Without Autocad

TO USE 'SMART OPEN': From the Unisoft software click FILE from the main menu, click SMART OPEN and a new window opens. In the new window browse to and select the directory that your project CAD or Gerber files are located in. A new window opens and select one of the files presented and your PC Board will be displayed.

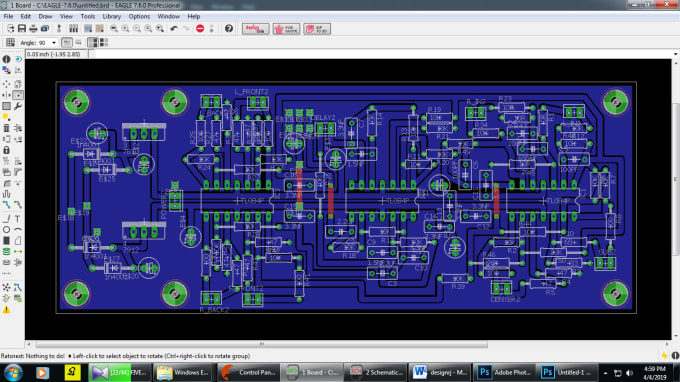

Each AutoCAD-based product uses by default a specific file format when saving to a file, which is important to know when sharing files. DWG files can be opened using any AutoCAD or AutoCAD product of the same version number or later. For example, AutoCAD 2017 will not be able to open DWG files from newer versions such as AutoCAD 2020. It is one of the best free CAD software systems that is loved by engineers and electricians around the world. It is an open-source PCB design software that comes with a built-in project manager and four powerful utilities including a printed circuit board editor, schematic editor, footprint selecting tool and the GERBER file viewer/editor. Use GerbLook to view your PCB design online for free. No download required. Upload your Gerber 274x files and select solder mask, silkscreen and copper colors to generate an image of your layout as a manufactured circuit board.

IPC-2581 is a generic standard for PCB assembly and manufacturing description data and transfer methodology. Developed in 2004 by IPC, IPC-2581 is again like other two is used for transferring information between a PCB designer and a manufacturer or assembler. For almost every step in the process flow, IPC-2581 offers a guideline to help companies ensure superior manufacturability, quality, reliability and consistency in electronics assemblies built for their products.

Gerber Files

Open Autocad Files Free

The most widely used file format for PCB manufacturing is called Gerber. When manufacturers request “Gerbers” or “Gerber files,” they basically look for ASCII files that contain Gerber-formatted data. These are actually “CNC” files. They drive the photoplotter to create the film that is used to expose each conductor layer in the board. A Gerber file has no idea about design rules, net connectivity, or component libraries; it is simply two-dimensional artwork that indicates where the manufacturing equipment will place copper, solder mask, or silkscreen. One Gerber file provides information for one PCB feature on one layer. Thus, if you have a two-layer board and each side has Gerber files copper, solder mask, and silkscreen, you will need six Gerber files.